At Srinox Tube Solutions Pvt Ltd, inspection and testing are fundamental to our commitment to delivering premium-quality stainless steel products. We follow a rigorous quality assurance system that includes a comprehensive suite of tests to ensure our products not only meet but exceed industry standards. These evaluations are conducted at both in-process and final inspection stages and are broadly classified into two key categories.

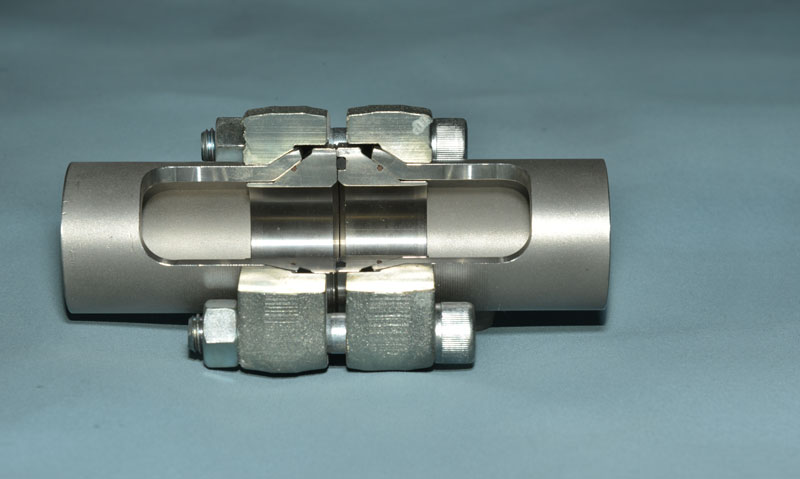

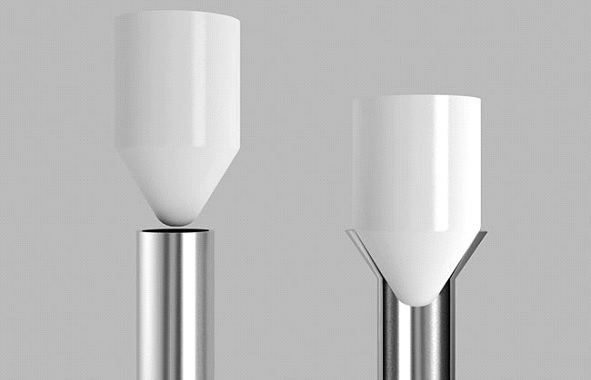

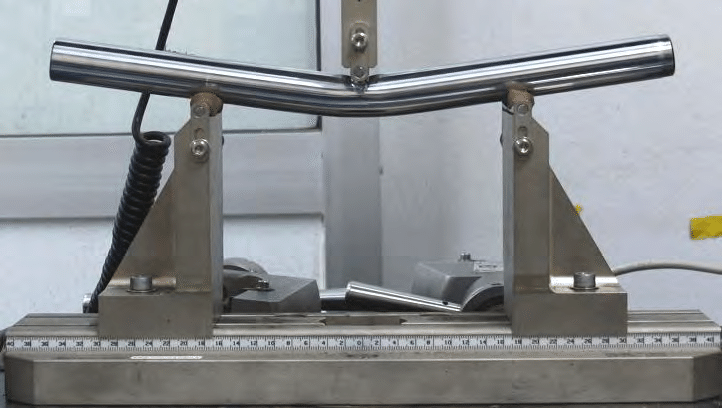

The first category includes physical testing, where we thoroughly assess the structural integrity and mechanical performance of our stainless steel pipes and tubes. These evaluations cover dimensional accuracy, tensile strength, hardness, and elongation. Through these detailed physical tests, we ensure our products are durable, reliable, and well-suited for diverse industrial applications.

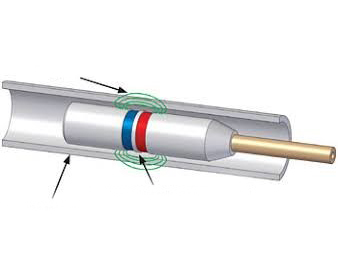

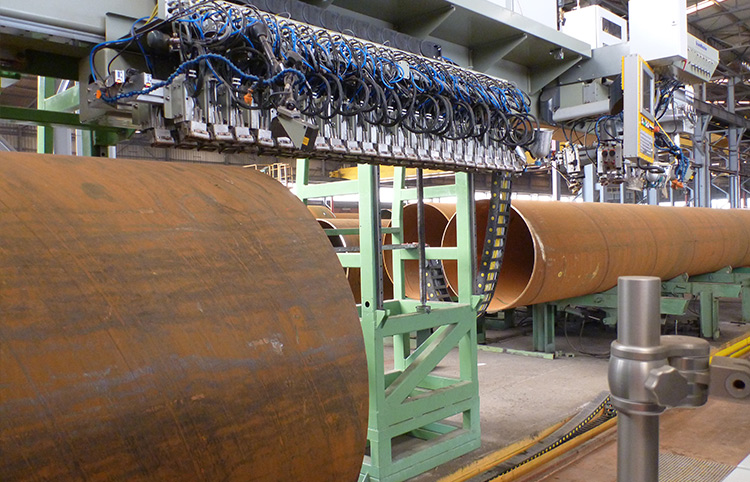

The second category involves advanced non-destructive testing (NDT) techniques aimed at identifying internal or surface-level imperfections without affecting product integrity.